Packaging plays a crucial role in building a brand’s image and catching the attention of potential customers. With the vast array of packaging options available, selecting the best one for your product can be challenging. However, embossing and debossing are excellent techniques that add elegance to your packaging and make your product stand out.

In this article, we will explore everything you need to know about embossing and debossing packaging, including their benefits, differences, and how to use them effectively to elevate your brand’s image.

What is Embossing?

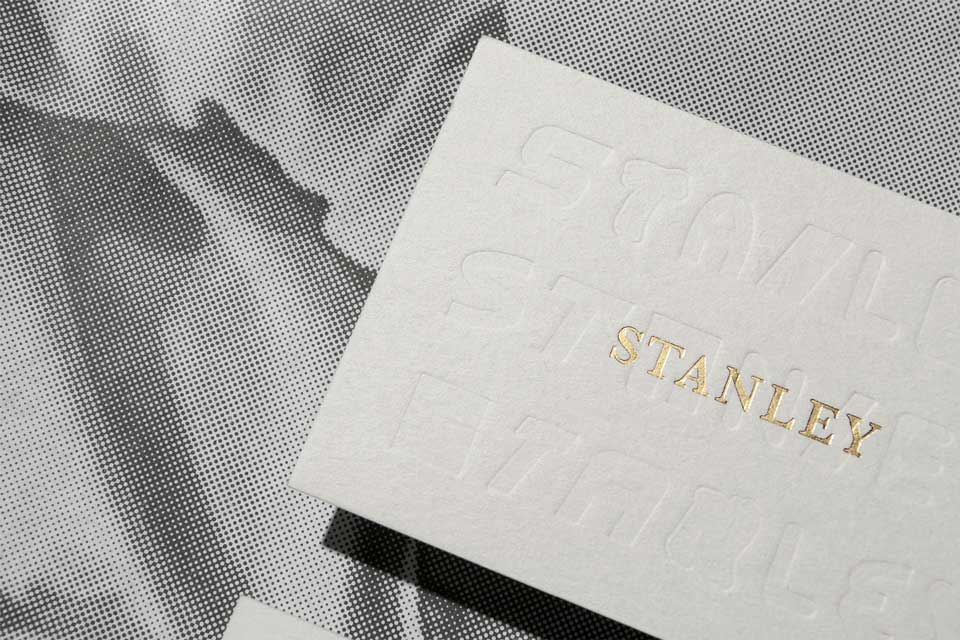

Embossing is a technique that involves creating a raised 3D design on the surface of a material. The process typically involves using a metal die, which is pressed onto the material with heat and pressure, leaving an indentation of the design. This indentation is filled with ink or foil to create a visually stunning effect.

Embossing can be used on various materials, including paper, cardboard, and even leather. It can also be applied to different packaging areas, such as the logo, text, or graphics, to create a striking visual contrast.

Benefits of Embossing

- Adds texture and depth to custom packaging

- Enhances the tactile experience for customers

- It creates a premium and luxurious feel

- Increases brand recognition and memorability

What is Debossing?

Debossing, on the other hand, involves creating a depressed or sunken 3D design on the surface of a material. It is the opposite of embossing and consists of pressing the die into the material to make an indentation.

Debossing can be combined with other printing techniques, such as foil stamping or letterpress, to create a visually stunning effect. It can also be used on different packaging areas, such as the logo or brand name, to create an elegant and sophisticated look.

Benefits of Debossing

- Adds a subtle and understated elegance to packaging

- Enhances the tactile experience for customers

- Creates a premium and high-quality feel

- Increases brand recognition and memorability

Differences Between Embossing and Debossing

While embossing and debossing may seem similar at first glance, the two techniques have some fundamental differences.

Embossing creates a raised design on the material’s surface, while debossing creates a hollow or depressed design. Embossing is typically used to create a striking visual contrast, while debossing is more subtle and understated.

Another key difference is how the two techniques interact with light. Embossing reflects light, creating a shiny effect, while debossing absorbs light, creating a matte and textured effect.

How to Use Embossing and Debossing in Your Custom Packaging

Embossing and debossing can be used in various ways to elevate your brand’s image and create a memorable customer experience. Here are some tips on how to use these techniques effectively:

1. Highlight Key Elements

Embossing and debossing can draw attention to critical elements of your packaging, such as the logo, brand name, or tagline. By creating a raised or depressed design, you can make these elements stand out and create a visually stunning effect.

2. Add Texture and Depth

Embossing and debossing can add texture and depth to your packaging, creating a tactile experience for customers. This can be especially effective for products meant to be touched or held, such as cosmetic packaging or luxury goods.

3. Create a Premium Look and Feel

Embossing and debossing can create a premium, high-quality look and feel for your packaging. By adding a 3D design, you can make your packaging stand out from the competition and create a memorable customer experience.

4. Use in Combination with Other Techniques

Embossing and debossing can be combined with other printing techniques, such as foil stamping, letterpress, or spot UV, to create a visually stunning effect. Combining these techniques allows you to create a unique and eye-catching design for your packaging.

5. Consider the Material

When using embossing or debossing, it’s essential to consider the material of your packaging. While these techniques can be used on various materials, such as paper or cardboard, they may not work well on certain materials, such as plastic or metal.

Conclusion

Embossing and debossing are excellent techniques that elevate your brand’s image and create a memorable customer experience. By adding a 3D design to your packaging, you can create a premium, high-quality look and feel that will stand out from the competition.

Whether you choose to use embossing, debossing, or a combination of both, it’s essential to consider the material of your packaging, the key elements you want to highlight, and the overall look and feel you want to create.

By effectively using these techniques, we can help you create a packaging design that looks great and enhances the overall customer experience.

Cosmetics Boxes

Cosmetics Boxes Display Packaging

Display Packaging Eco Friendly Boxes

Eco Friendly Boxes Food & Beverage

Food & Beverage Gift Boxes

Gift Boxes Metalized Boxes

Metalized Boxes Retail Boxes

Retail Boxes View all industries

View all industries Custom CBD Boxes

Custom CBD Boxes CBD Display Boxes

CBD Display Boxes CBD Tincture Boxes

CBD Tincture Boxes E-Liquid Boxes

E-Liquid Boxes Vape Cartridge Boxes

Vape Cartridge Boxes Bottom Closure

Bottom Closure Fold & Assemble

Fold & Assemble Figure & Pattern

Figure & Pattern Rectangular

Rectangular Top Closure

Top Closure